Milking is an essential process within the agricultural industry, and it is certainly not an easy task. Obviously, with the current huge growth of the milk and dairy industry, people are not still milking their cows by hand on a large scale. So, how does the industry manage this?

The Milk Parlor was an incredibly important invention in this area. Mechanization and optimization of the milking process are essential to managing the boom in the dairy market. Understanding the best ways to milk your cows is extremely important to keep you ahead of the competition in this field.

This article outlines the 7 different types of Milking Parlor out there, briefly considering the positives and negatives of each one. We cover tandem, herringbone, parallel, rotary, chute, robotic and parabone methods of milking groups of cows in one go.

Alongside this we will take you through some basic concepts of the milking parlor, whether or not they are good for your cows and the various associated pros and cons of the process.

If that is at all in your area of interest, then read on!

What is a Milking Parlor Anyway?

Despite what some children may have us believe, strawberry milk does not come from pink cows. That aside, the good wholesome white stuff promotes bone growth, strength, and nutrient management within the body. So, the question remains, how does it get from the cow to the pint bottles?

Obviously, the answer is “milking”, but that word means something different in a modern, industrialized, and mechanized world (and associated dairy market). No longer do we have to sit patiently at stools to milk cows, we can get the help of robots, machines, and efficient organization to make this process go lightning fast.

What is a Milking Parlor?

A milking parlor is a room or structure designed to mass milk a large group of cows at once.

These can be large rooms, specific factories or warehouses, your own barn or even an outside portable milker setup, and all of them speed up the milking process.

One Dorset farm is known for its free-range and wide-roaming cattle herds, and uses a unique milking parlor that is moved outside to wherever the cows are! Sometimes the cows get treated better than the farmers.

Are They Good for Cows?

While milking parlors are certainly great for the dairy industry, are they any good for cows?

The parlors run for upwards of 20 hours every day and milk each cow in a large herd approximately three times that day. This is not only more stressful for the cow than traditional milking methods, but they also massively increase the chance of teat disease.

Milking parlors are normally quite expensive, and if they are not cleaned properly and frequently they can soon become big contact points for the transfer of disease in the udders of your herd.

What are the Pros and Cons of Milking Parlors?

Pros

Cons

The 7 Best Milking Parlor Types:

1. Tandem

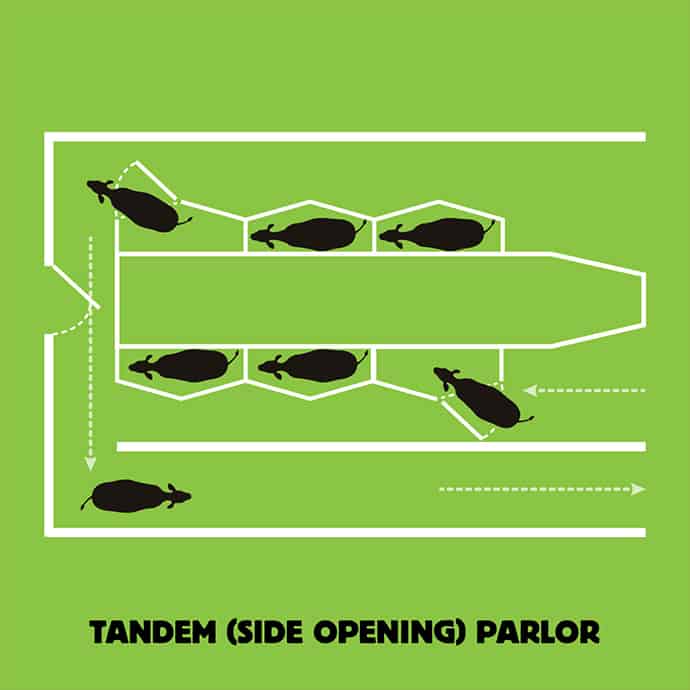

This method of milking parlor design deployment closely follows the philosophy of the tandem bicycle. The tandem bike has two people sat in series on the bicycle during cycling.

Much like that vehicle, the tandem milk parlor arranges cows in series, in a nose to the tail formation. This allows the parlor side-on access to the cow’s udder. Cows can also be released one at a time to avoid free movement blockages from slow bovines.

Source: Dairy Discovery Zone

These are side-opening stall types of parlors, each of which is made for a single cow. Tandem parlors are designed to give the milker a side view of the udder. Cows can be released one at a time or several at a time since they all have their own doors. The entrance and exit flow of facilities with these stalls are in one direction.

Pros & Cons of Tandem Milking Parlor

2. Herringbone

The Herringbone system is by far and away the most common in milking parlors around the world.

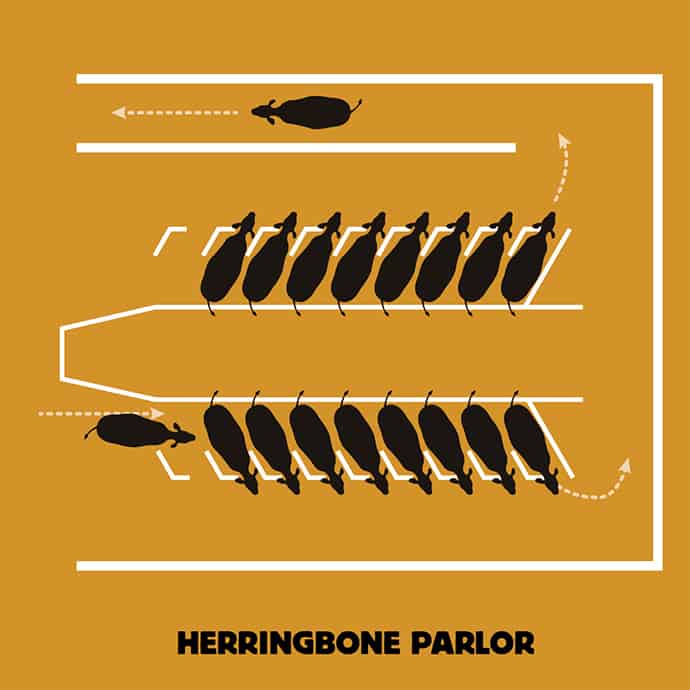

Cattle are arranged at 45-degree angles away from the machine, which allows for a unique access angle for milkers and for farmhands to arrange different equipment near the cows as well.

The cattle are in rows, side to side with each other at 45-degree angles, kind of like many parking lots.

Source: Dairy Discovery Zone

In this milking parlor design, cows stand on a raised platform “in an angled or herringbone fashion facing away from the operator area.” This positioning lets a worker see the back half of the cow and get up to it for milking from the side with space for an arm-type detacher.

A one-way system assures quick and efficient movement of cattle through the machines.

Pros & Cons of Herringbone Milking Parlor

Also Read: Do Cows Feel Pain When Milked?

3. Parallel

In a Parallel parlor, cows are unsurprisingly arranged in parallel to each other. Think straight-in parking. This milking parlor only sets itself underway when every cow is loaded in, having one central access point for people to get to the cows (namely the rear end).

There is a one-way system in place as well to avoid blockages and movements, as is standard with a lot of milking parlor.

Pros & Cons of Parallel Milking Parlor

4. Rotary

A rotary parlor functions a lot like a merry-go-round or carousel for cows. They enter through one way, get into their pod, and the machine spins them around the rotary function while milking. In theory it should arrive them right back at the entrance once they are finished milking.

After that the cow can exit. As it spins, a new slot will open for another cow to take its place. The stalls are set in a circle along the perimeter of a platform, and there is only one entrance and one exit for the cows

This is theoretically a more efficient way of constructing a milking parlor as it wastes no time between cows getting into the pods and the next cow getting on.

Pros & Cons of Rotary Milking Parlor

Types of Rotary parlors

Rotary Abeast Parlor

Regarding size and cost, this is the cheapest version of the rotary parlor per cow. Its platform has no moving parts, and cows face the middle and are divided by tubular metal panels. From the perimeter of the platform, the dairy worker can help cows enter but cannot see them during rotation.

Rotary Tandem Parlor

This one is the most expensive per cow relative to commercial space and cost of the rotary versions. In a circle around the operator’s workspace, the cows are lined up nose-to-tail. That worker can see the sides, front, and rear of all the cattle while the platform turns but doesn’t have access to assist the cows’ entry.

Rotary Herringbone Parlor

In terms of cost, this one is in the middle of the three rotary styles. The cows stand facing outward from the middle work area. Dairy workers can see most of the cows as the platform rotates, but not as much view as the Rotary Tandem.

5. Chute

A chute parlor is a cheaper, batch farming version of the tandem milking parlor. Cows are arranged much like the tandem parlor in a nose to tail formation.

The cows enter the stalls and then depart through the next stall when they are all released. That means, the cattle are in the same arrangement, one behind another in a line, but when they exit the dairy, it’s straight out in the direction they’re facing rather than a circle back to the same side into which they entered.

So, the cows enter one end of the parlor, complete milking in a stall, and then continue forward, some through other stalls, until out of the dairy. This improves somewhat on the regular tandem system with these optimizations.

Pros & Cons of Chute Milking Parlor

6. Robotic

A robotic milking parlor is just that, a set of robots that milk your cows.

The robot can be programmed to only process certain cows several times a day, with the option for further milking sessions if the cow wants to do so.

These make milking much more efficient, as they do not have to take breaks and can figure out the most optimal way to extract milk from one’s herd. These machines connect to a cow’s teat of their own accord, extract the necessary milk, and automatically release the teat when finished.

It is certainly not a scene from a science fiction film, in fact robotic milking parlors may well be the future of the dairy industry!

Also, the cows have a transponder around their necks with number codes to identify them. Each cow can be identified by its specific number code. When a cow enters and settles into its milking stall, the robot reads the number during the milking process and provides color-coded data to the farmer showing the stage of the milking operation.

Pros & Cons of Robotic Milking Parlor

7. Parabone

As the name might suggest, a parabone milking parlor merges the parallel and herringbone setups for a milking a large swathe of your herd at once.

The angle is much steeper than that of a herringbone setup, something around 70 degrees (but always less than 90). This allows them to be arranged in parallel, fitting in many more cows than the traditional herringbone.

The one-way system from both is still in place, and these angles allow for access to the udders from between the two back legs of the animal. The arrangement eliminates any possibility of side milking, however.

Milk lines in this setup are usually placed above the heads of farmhands for the most efficient milking possible.

Parabone is typically the choice for farmers with limited space capacity and want a herringbone setup to fit their space. This setup allows a massively increased level of milk production from a whole host of new cows.

Pros & Cons of Robotic Parabone Parlor

Final Thought

To conclude, the milking parlor is one of the most important components of any dairy farm. It increases milking efficiency and makes dairy farmer’s job easier. Further enhancements can be done by combining different types of milking parlors as needed.

No matter whichever Milking parlor system you use, the most important considerations for your choice are, efficient milking processes, high throughput with maximum yields, animal-friendly stall design and labor-safe platform.

Interested in reading about the Milking machine operation? Do check useful information on How a milking machine work on a dairy farm.